×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz C230 Brake Pad Set

Disc Brake Pad Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Pad Sets found

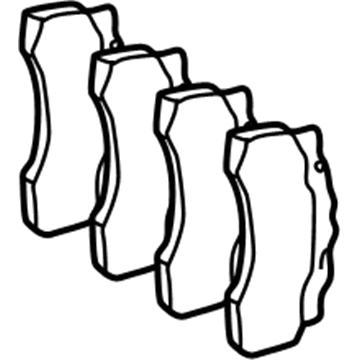

Mercedes-Benz C230 Brake Pads

Part Number: 003-420-28-20-90$45.60 MSRP: $64.00You Save: $18.40 (29%)Ships in 1-2 Business DaysMercedes-Benz C230 Brake Pads

Part Number: 004-420-02-20-41$73.20 MSRP: $102.00You Save: $28.80 (29%)Ships in 1-2 Business DaysMercedes-Benz C230 Rear Pads

Part Number: 004-420-91-20-41$57.00 MSRP: $80.00You Save: $23.00 (29%)Ships in 1-2 Business DaysMercedes-Benz C230 Front Pads

Part Number: 005-420-46-20-41$55.80 MSRP: $78.00You Save: $22.20 (29%)Ships in 1-2 Business Days

Mercedes-Benz C230 Brake Pad Set

Every OEM part goes through strict quality checks. The checks keep you safe and make Brake Pad Set tough. They keep performance the same as your original parts. If your Mercedes-Benz C230 needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz C230 parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz C230 Brake Pad Set Parts and Q&A

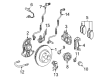

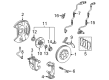

- Q: How to replace Brake Pad Set on floating and fixed calipers on Mercedes-Benz C230?A:Most of the models are equipped with floating calipers on the front and fixed calipers on the rear but it can have fixed calipers on all sides. The difference between these type calipers is the piston layout and how they are mounted, the fixed type having one or two pistons at either side of the disc and mounted directly to the steering knuckle, the floating type having one or two pistons just at one side and attached to a mounting bracket which is attached with an eye of the vein to the steering knuckle. Before changing brake pads, you need to make sure there are as many brake pad wear sensor connectors on one caliper as there are on the other ones you/she can see on the rear of the sensor connectors. Start by taking the cap out of the brake fluid reservoir and filling the fluid all the way down to the MIN mark. Unscrew the wheel bolts and hoist the vehicle then set it on jackstands, blocking the wheels on the other end. Take the wheels out and check the Brake Disc; maybe a machining is necessary, then follow the procedure to take away disc and pad. In floating calipers, only by pushing the piston back into the bore longitudinally with a C-clamp can the master cylinder fluid not overflow. Disattach connectors of pad wear sensor, unscrew bolts connecting caliper mounting piece and raise caliper tying it with wire. Removal of the outer and inner pads, inspection and replacement of any tear wear sensors, check of the anti-rattle clips. Wipe down the guide pins, wash them and put them back in, being sure to adjust the boots. Place the inner pad and then the outer pad with thread-lock connecting bolts into the caliper assembly and then tighten them. With fixed calipers, a punch is used to clear the pins holding the brake pad, with reference to the direction of the spring, and force the pistons back into the caliper bore. Wipe down the surfaces the brake pad plates have been in contact with and put in the new pads, snapping them into place with the spring and holding pins. Once again after the job, press the brake pedal to ensure the pads touch the disc, customer check the level of brake fluid, and add more, where needed. Lastly, assemble the wheels, lower the vehicle, tighten the wheel bolts, pump the brake pedal, then verify the amount of fluid again then finally verify that the brakes are functional.