×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz C240 Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Shock Absorbers found

Mercedes-Benz C240 Shock Absorber

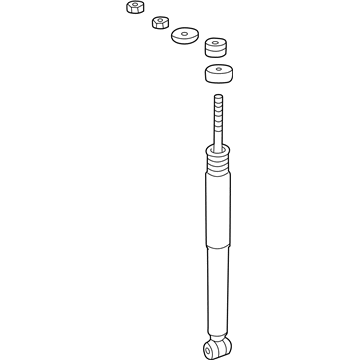

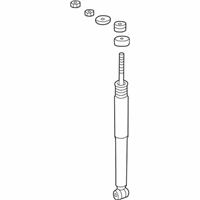

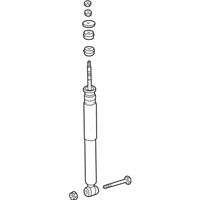

Part Number: 203-326-36-00$146.40 MSRP: $204.00You Save: $57.60 (29%)Ships in 1-2 Business DaysMercedes-Benz C240 Shock Absorber

Part Number: 203-326-29-00$157.20 MSRP: $220.00You Save: $62.80 (29%)Ships in 1-2 Business DaysMercedes-Benz C240 Shock Absorber

Part Number: 203-326-17-00$194.40 MSRP: $270.00You Save: $75.60 (28%)Ships in 1-2 Business Days

Mercedes-Benz C240 Shock Absorber

Every OEM part goes through strict quality checks. The checks keep you safe and make Shock Absorber tough. They keep performance the same as your original parts. If your Mercedes-Benz C240 needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz C240 parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz C240 Shock Absorber Parts and Q&A

- Q: How to check front CV Joint Boot and rear Shock Absorber on on Mercedes-Benz C240?A:Periodically check steering linkage and suspension components also: used or damaged parts can cause excessive tire wear, poor ride quality, handling problems and poor fuel economy. To test the shock absorbers, turn the engine off, apply parking brake on level ground and then measure the tire pressures. Press on one end of the vehicle, then release and ensure the vehicle does not move: It only takes 1 or 2 bounces back to its level position, any further it may be of low quality, the shock absorber is weak. Check the same at the opposite corners and then elevate the vehicle on jackstands. Check the presence or absence of fluid leakage in the shock absorbers making sure that any observed fluid leaks is due to shocks and in this case change the set. confirmation and damages Check secured mounting and if any is problematic then replace as a set. With steering and suspension, the components should be visually examined to be damaged, distorted, and leaking, especially where there are seals and boots. Wipe the lower knife-end of the steering joint and have jockey move up and down the steer with the assistant watching whether the joint is turning or not; anything turning shows it must be changed. You must hold all the tires on the front and test the play. Driveaxle boots play a significant role in shielding the constant velocity joints against dirt and damage; make sure they do not have any tears, cracks or loose clamps, any of which can indicate wear and leaking lubricant.

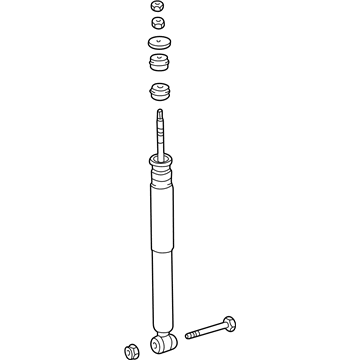

- Q: How to remove and install the shock absorber in the trunk compartment on Mercedes-Benz C240?A:In the trunk compartment, remove the rear trim panel and lining fasteners, then pull the carpeting aside to access the shock absorber's upper mounting nut. For round-headed fasteners with a circle in the center, pry the center out and then pull the entire fastener out; if there is no circle, pry the entire fastener out. For small flat rectangular fasteners, use the small slots on the sides to pry them up. For wagon models, remove the rear-most storage compartment covers on each side of the cargo area. Next, remove the upper mounting nut and hardware by holding the damper rod and loosening the nut, then discard it. Raise the rear of the vehicle and support it securely on jackstands, ensuring the jackstands are placed under the frame and not any suspension components. Remove the cover from the spring link by taking out the two screws and unclipping the cover. Detach the fasteners that connect the lower end of the shock to the spring link, applying penetrating oil if the fasteners seem frozen. Finally, installation is the reverse of removal, using new self-locking mounting nuts and tightening them to the specified torque.