×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz C280 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Discs found

Mercedes-Benz C280 Rotor

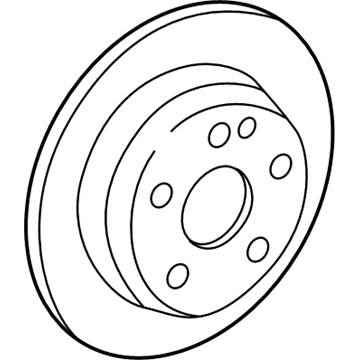

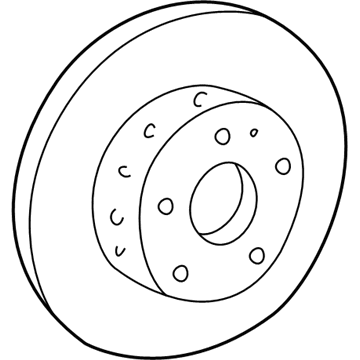

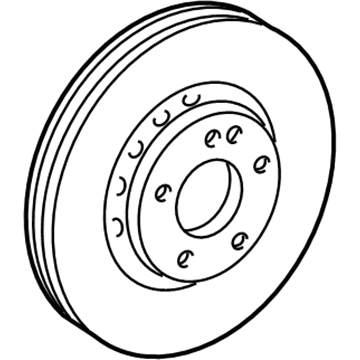

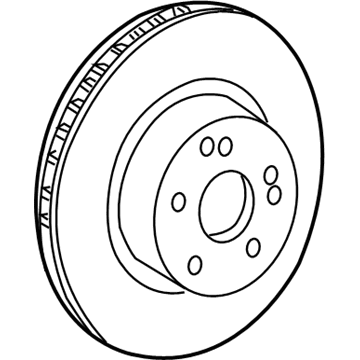

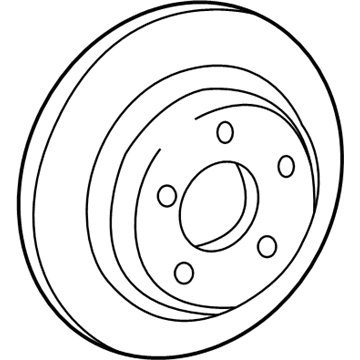

Part Number: 210-423-10-12-90$44.39 MSRP: $62.00You Save: $17.61 (29%)Ships in 1-2 Business DaysMercedes-Benz C280 Rotor

Part Number: 202-421-09-12-64$58.80 MSRP: $82.00You Save: $23.20 (29%)Ships in 1-2 Business DaysMercedes-Benz C280 Rotor

Part Number: 203-421-03-12-90$54.00 MSRP: $75.00You Save: $21.00 (28%)Ships in 1-2 Business DaysMercedes-Benz C280 Rotor

Part Number: 203-421-09-12-90$90.00 MSRP: $125.00You Save: $35.00 (28%)Ships in 1-2 Business Days

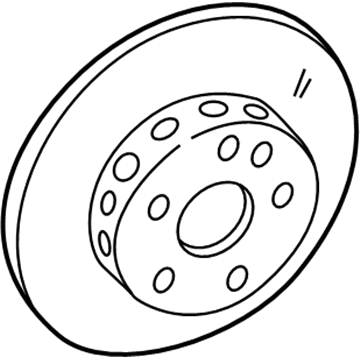

Mercedes-Benz C280 Brake Disc

Every OEM part goes through strict quality checks. The checks keep you safe and make Brake Disc tough. They keep performance the same as your original parts. If your Mercedes-Benz C280 needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz C280 parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz C280 Brake Disc Parts and Q&A

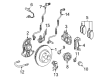

- Q: How to inspect and replace brake discs on Mercedes-Benz C280?A:Other models have cross-drilled front brake discs to cool during hard braking, although such discs can not be machined on normal brake lathes. In the case of a defected or warped disc, the direction with the lowest cost could be replacement. Start by loosening the wheel bolts, raising the vehicle, and then mounting the vehicle safely on jackstands, then remove the wheel. Secondly, before we disconnect the Brake Hose, we just unscrew one of the Brake Caliper and leave it hanging with wire to prevent undue stresses on the hose. To secure the disc against the hub, should any be necessary, reinstall some wheel bolts or examine the disc surface surface to see whether there are any light scratches, deep marks, or wide cracks, which might need replacement. Check the holes in the cross-drilled discs about the presence of brake dust, and remove it, taking care not to extend the diameter. A dial indicator must be used to inspect the disc runout, 0.003 inches or above could need cleaning or changing. Without machining the disc below the stipulated minimum thickness which is cast in the disc. To remove, clean all mounting bolts and apply thread-locking compound when mounting. Disassemble the caliper of the brake, including its mounting bracket, screw that holds on the disc, the disc, and other wheel bolts where applicable, with a mallet, as required. Rinse out the hub flange and the inside of the brake disc thoroughly using anti-seize compound to stop rust. Place the disc in the hub, screw on the retaining screw and reassemble the brake caliper and pads with all bolts tightened to the recommended value. The last thing to do is place the final part, the wheel, lower the vehicle, connect the wheel bolts, and pinch the brake pedal in place until the brakes work.