×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz C320 Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Brake Booster found

Mercedes-Benz C320 Brake Booster

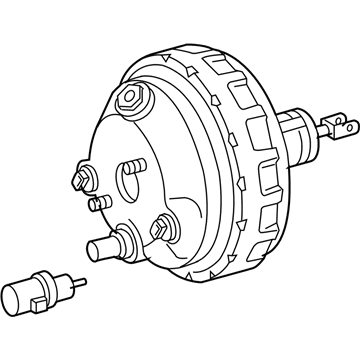

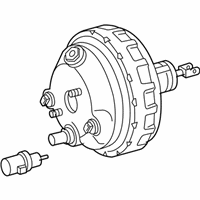

Part Number: 005-430-55-30-28$600.00 MSRP: $835.00You Save: $235.00 (29%)Ships in 1-2 Business Days

Mercedes-Benz C320 Brake Booster

Every OEM part goes through strict quality checks. The checks keep you safe and make Brake Booster tough. They keep performance the same as your original parts. If your Mercedes-Benz C320 needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz C320 parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz C320 Brake Booster Parts and Q&A

- Q: How to check, remove, and install a power brake booster on Mercedes-Benz C320?A:On some V6 engine models, a small vacuum pump may be added to the power brake booster system, serving as the vacuum source for the booster, which is mounted to a bracket behind the right headlamp housing with a large diameter vacuum hose routed to the brake booster. If the system appears defective, diagnosis by a dealer service department is required. To check operation, depress the brake pedal several times with the engine off to ensure no change in pedal reserve distance, then start the engine; if the pedal goes down slightly, operation is normal. For an airtightness check, start the engine and turn it off after one or two minutes, then depress the brake pedal slowly several times; if the pedal depresses less each time, the booster is airtight. While the engine is running, depress the brake pedal, stop the engine with the pedal depressed, and if there's no change in pedal reserve travel after holding for 30 seconds, the booster is airtight. The power brake booster is not serviceable and should be replaced if defective. To remove it, with the engine off, press the brake pedal several times to remove stored vacuum, move the driver's seat to the rearmost position, and disconnect the negative battery terminal. Remove the windshield wiper motor and linkage, the Brake Master Cylinder, and pull the vacuum hose fitting from the brake booster while leaving the vacuum hose attached. Remove electrical connectors from any sensors and switches mounted to the power brake booster, noting that models equipped with ESP will have components that need to be transferred to the replacement booster. Release wire harnesses from the separator inside the engine compartment and from the fuse and relay box, ensuring the Powertrain Control Module (PCM) is pulled out of the box for harness slack without disconnecting it. Remove the lower instrument panel insulator for access, the brake light switch if equipped, and the plastic cover over the brake pedal. Carefully pry off the retaining clip from the brake pedal pin, pull the pin from the brake pedal and pushrod clevis, disconnect the booster pushrod, and remove the booster mounting nuts. Slide the booster straight out from the firewall until the studs clear the holes. Installation is essentially the reverse of removal, ensuring to replace the seal between the power booster and the firewall, avoid dropping anything into the replacement booster when transferring sensors and switches, tighten the booster mounting nuts to the specified torque, reinstall the retaining clip securing the booster pushrod to the brake pedal pin, and bleed the master cylinder and brake system before testing the operation of the brakes.