×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz 190E Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Calipers found

Mercedes-Benz 190E Caliper

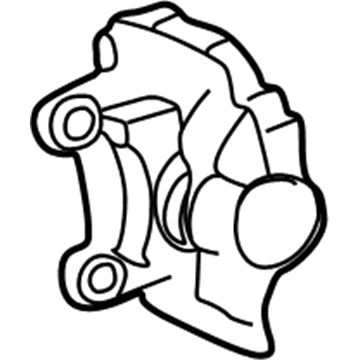

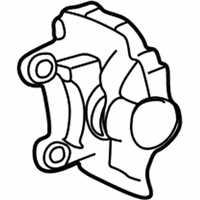

Part Number: 201-420-02-83-64$268.08 MSRP: $371.50You Save: $103.42 (28%)Ships in 1-2 Business DaysMercedes-Benz 190E Caliper

Part Number: 201-420-03-83-64$275.28 MSRP: $381.50You Save: $106.22 (28%)Ships in 1-2 Business DaysMercedes-Benz 190E Caliper

Part Number: 000-420-51-83$150.27 MSRP: $208.00You Save: $57.73 (28%)Ships in 1-2 Business Days

Mercedes-Benz 190E Brake Caliper

Every OEM part goes through strict quality checks. The checks keep you safe and make Brake Caliper tough. They keep performance the same as your original parts. If your Mercedes-Benz 190E needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 190E parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 190E Brake Caliper Parts and Q&A

- Q: What are the steps involved in the removal, overhaul, and refitting of a front brake caliper on Mercedes-Benz 190E?A:Hydraulic fluid and asbestos dust are some of the dangers to be aware of before commencing work. Stronger brake caliper guide pin bolts will be needed after fixing them. Start by putting on the parking brake, lifting the front of the car on axle stands and then taking the relevant roadwheel off. When possible, reduce the loss of fluids using polythene that has been used to cover the reservoir cap of the master cylinder or a Brake Hose clamp. Wipe out the vicinity between the union and loosen nut on the brake hose union at the caliper and remove the brake pads. unscrew the caliper, take it off the brake hose, slacken and remove the upper guide pin bolt. Wipe dust and dirt off the bench without breathing it in. Pull the half-piston out and take off dust seal, and proceed to take off piston hydraulic seal. Wipe clean with methylated spirit, isopropyl alcohol or clean hydraulic fluid without use of solvents (mineral based solvents are discouraged). Inspect all parts that could be damaged or worn, especially the cylinder bore and the piston, and replace damaged and scratched or corroded parts. In case the assembly can be used again, get the relevant repair kit, all rubber seals should be replaced. When reassembling, clean and dry all parts, immerse the piston and new piston seal in clean hydraulic oil/fluid, and wipe clean fluid on surface of cylinder bore. Install the new piston seal mold with finger, and install the new dust seal and slip the piston into the bore. When changing guide pin lubricate the gaiters with special grease and then install the gaiters on the shaft of the pins. Install the new caliper onto the flexible hose union, scrape all old locking compound off the threads in the caliper guide pin/bolt hole, screw the caliper into the threads in the screwish part of the new upper guide pin, and install the new upper guide pin screwdriver bolt with specified torque listed. Tighten the union nut of the brake hose and remove the Polyethene or brake hose clamp. Redisconnect and refit the brake pads and rebleed the hydraulic system with as little brake fluid loss as possible. Re-fasten the roadwheel, de-lift the vehicle and screw the roadwheel bolts to the recommended torque. Lastly, before putting a vehicle back into service, it is important to test the braking system in a detailed manner and to check the machine fluid level.