×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

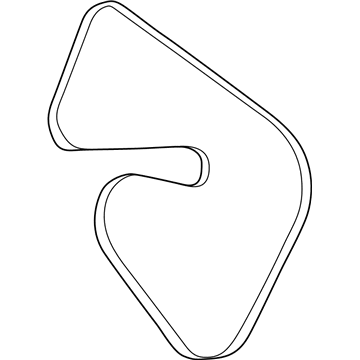

Genuine Mercedes-Benz 300TD Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Drive Belt found

Mercedes-Benz 300TD Drive Belt

Every OEM part goes through strict quality checks. The checks keep you safe and make Drive Belt tough. They keep performance the same as your original parts. If your Mercedes-Benz 300TD needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 300TD parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 300TD Drive Belt Parts and Q&A

- Q: What is the role and maintenance of drive belts in vehicle operation on Mercedes-Benz 300TD?A:The drivebelts or V-belts are placed on the front of the engine and are very important to the operation of the vehicle and its parts. These belts are vulnerable to failure after some time due to their functionality and the material used in making them, so one needs to keep checking and adjusting them within a specified time frame to prevent major engine damages. The ribbed belts used by vehicles are of a particular design that should under no circumstance be substituted with belts of different or similar design. How many belts depends on the accessories installed as drivebelts have the responsibility of turning the generator/alternator, water pump, power steering pump, vacuum pump, air-conditioning compressor; a single belt can be used to power several items depending on the pulley system. To examine the belts, when the engine is off, open the hood and find the belts at the front of the engine and look for cracks and separation of the belt plies, fraying and glazing on both sides by twisting the belt and then examining the underside. It is possible to measure the tension of the belt using a Gates or Borroughs tension gauge, or working between the pulleys by pushing the belt (a general rule of thumb would be 1/4 inch deflection with a 7- to 11-inch belt and 1/2 inch deflection with a 12- to 16-inch belt). Adjustment of the belt tension can be done through transferring the belt-driven accessory on its bracket by loosening an adjusting bolt and pivot bolt to slide the part back and check the tension. Once the appropriate tension is reached the bolts must be tightened until tight, and then the tension checked again. The accessory may need to be repositioned with the help of a pry bar to gain leverage, although care is taken not to destroy the part or the material being pried.