×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz 190E Throttle Cable

Accelerator Throttle Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Throttle Cable found

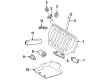

Mercedes-Benz 190E Throttle Cable

Every OEM part goes through strict quality checks. The checks keep you safe and make Throttle Cable tough. They keep performance the same as your original parts. If your Mercedes-Benz 190E needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 190E parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 190E Throttle Cable Parts and Q&A

- Q: How to remove, refit, and adjustment of the Throttle Cable in the Carburettor fuel system on Mercedes-Benz 190E?A:The throttle cable should be removed; remove the inner cable off the carburettor guide lever: prise out the square retaining block and prise out the cable inner down the slot on the guide lever bracket. Then squeeze the buttons on the plastic retainer to loosen the outer cable in its bracket. In the driver footwell, loosen the return spring, extract the circlip and disconnect the inner cable by tipping it over on the top of the pedal arm. Be careful with the outer cable when pushing the cable through the bulkhead grommet and do not push out the grommet itself but at the outer bulkhead draw out the rubber grommet and pull the cable into the engine compartment. To re-fit, repeat the steps in reverse, this time taking care to reposition the operation of the linkage and cable before refitting them to the carburettor. To break in, get the engine going to normal temperature and turn it off. Where actionable, remove the cruise control/air conditioning control work rod and the control pressure cable off the guide lever. With Stromberg carburettor models that use another type of throttle lifter, which is a vacuum throttle lifter, start the engine, squeeze the throttle lifter vacuum hose, stop the engine, and check the clearance of the throttle linkage lever against the adjusting screw, adjusting it accordingly. In the Stromberg models, when the throttle cable is disconnected, loosen the screw of the progressive link (and) fitting between the roller and the idle stop has been reached, and then screw it tight. On models that have a Pierburg carburettor, pull throttle actuator plunger out of position, shift idle travel control rod by about 0.5 mm degree travel and re-connect throttle other light. When it has an adjustable full throttle stop behind the pedal, simply switch the stop pin to the left and press it out a bit. Push the throttle pedal (manual transmission) all the way open, or an automatic throttle pedal all the way to the kickdown switch, so that the throttle lever is touching the full throttle stop plate. Adjust the nut where the support bracket is located, as necessary, to obtain this contact. The throttle pedal should also be released by pushing the throttle pedal, letting the linkage roller leave the idle speed stop, and lock the full throttle stop pin where available. Make sure that the throttle cable nipple sits directly on the base of the compression spring with no free-play; adjust the nut on the throttle pedal end as necessary. Lastly, when relevant, pull the throttle actuator plunge vacuum supply tube off, reconnect and optionally reorient the cruise control/air conditioning control rod, and reconnect the control pressure cable in vehicles with active transmission and set the instrument to a new setting as needed.