×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz 300TD Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

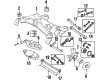

4 Wheel Bearings found

Mercedes-Benz 300TD Front Wheel Bearing

Part Number: 000-981-58-05$21.96 MSRP: $30.00You Save: $8.04 (27%)Ships in 1-2 Business DaysMercedes-Benz 300TD Front Wheel Bearing

Part Number: 000-981-59-05$28.06 MSRP: $38.50You Save: $10.44 (28%)Ships in 1-2 Business DaysMercedes-Benz 300TD Front Wheel Bearing

Part Number: 001-980-29-02$38.40 MSRP: $54.00You Save: $15.60 (29%)Ships in 1-2 Business DaysMercedes-Benz 300TD Rear Wheel Bearing

Part Number: 124-980-04-16$2.20 MSRP: $3.00You Save: $0.80 (27%)

Mercedes-Benz 300TD Wheel Bearing

Every OEM part goes through strict quality checks. The checks keep you safe and make Wheel Bearing tough. They keep performance the same as your original parts. If your Mercedes-Benz 300TD needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 300TD parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 300TD Wheel Bearing Parts and Q&A

- Q: How to check and repack front wheel bearings on Mercedes-Benz 300TD?A:With the vehicle securely supported on jackstands, spin the front wheels to check for noise, rolling resistance, and free play. Grasp the top and bottom of the tire and move it in-and-out; if it moves more than 0.005-inch, the bearings should be inspected and replaced if necessary. The front wheel bearings should be repacked with fresh grease and adjusted as part of routine maintenance. Raise the front of the vehicle and support it on jackstands, then remove the wheels. Detach the brake caliper retaining bolts and hang the caliper out of the way using a coathanger or wire, ensuring the rubber fluid hoses are not crimped or damaged. Remove the grease cap with large pliers, loosen the locknut with an Allen wrench, and take out the radio static suppressor using needle-nosed pliers. Remove the locknut and the hub while holding the outer bearing in place with your thumbs, then take out the outer bearing. Place the hub on a suitable surface and remove the inner bearing seal using a hammer and chisel, followed by prying it out with a screwdriver. Use solvent to clean all traces of old grease from the bearings, hub, and spindle, ensuring no bristles from the brush embed in the bearing rollers, and allow the parts to air dry. Inspect the bearings for cracks, scoring, and uneven surfaces; if defective, take the hubs to a machine shop for new races. Pack the bearings with approved high-temperature wheel bearing grease, ensuring it is forced between the rollers, cone, and cage. Apply a thin coat of grease to the spindle at the bearing seats and place a small quantity inboard of each bearing race inside the hub, forming a dam with your finger to retain grease. Install the grease-packed inner bearing into the hub and add more grease outboard of it. Lubricate the inner circumference of the new inner seal with grease, place it over the inner bearing, and tap it evenly into place with a hammer and suitable socket. Carefully position the hub assembly onto the spindle and push the grease-packed outer bearing into position. Install the locknut and adjust the bearing preload by rotating the hub while tightening the locknut until the bearings no longer turn, then back off the locknut 1/3 turn. Give the kingpin a sharp blow with a hammer to loosen the bearing tension, tighten the locknut Allen head screw securely, and install the radio static suppressor. Pack the cap with grease up to the bead and install it, tapping around the outer circumference to seat it. Finally, install the brake caliper(s), wheels, and check the wheel bearing play before lowering the vehicle.