×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz 190E Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Control Arms found

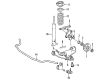

Mercedes-Benz 190E Upper Control Arm

Part Number: 124-350-77-06$44.40 MSRP: $62.00You Save: $17.60 (29%)Ships in 1-2 Business DaysMercedes-Benz 190E Lower Control Arm

Part Number: 124-350-51-06$98.40 MSRP: $137.00You Save: $38.60 (29%)Ships in 1-2 Business DaysMercedes-Benz 190E Control Arm

Part Number: 124-330-39-07$232.80 MSRP: $324.00You Save: $91.20 (29%)Ships in 1-2 Business DaysMercedes-Benz 190E Lower Control Arm

Part Number: 124-330-19-07$231.60 MSRP: $322.00You Save: $90.40 (29%)Ships in 1-2 Business DaysMercedes-Benz 190E Lower Control Arm

Part Number: 201-330-41-07$370.80 MSRP: $515.00You Save: $144.20 (28%)Ships in 1-2 Business DaysMercedes-Benz 190E Lower Control Arm

Part Number: 124-350-52-06$110.40 MSRP: $154.00You Save: $43.60 (29%)

Mercedes-Benz 190E Control Arm

Every OEM part goes through strict quality checks. The checks keep you safe and make Control Arm tough. They keep performance the same as your original parts. If your Mercedes-Benz 190E needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 190E parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 190E Control Arm Parts and Q&A

- Q: What are the steps involved in the removal, overhaul, and refitting of the Front suspension lower Control Arm pivot bolt on Mercedes-Benz 190E?A:Refitting will require new lower arm pivot bolt nuts, a balljoint clamp bolt nut, and anti-roll bar mounting clamp nuts. Start by first cleaning out the back wheels, putting the parking brake on and lifting the front of the car on a set of axle stands and then removing the right roadwheel and left roadwheel. Lift the plastic cover off the engine/ transmission side unscrewing the connecting screws. Unscrew and unscrew the retaining nuts that are holding the anti-roll bar mountings clamp on the front of the lower arm, then unscrew the rubber that secures the other mounting section. Install spring compressor to coil spring and press it in order to release tension between upper and lower seats. Place a piece of wood or block of wood and a jack under the lower arm, and loosen until the weight of the arm is carried by the jack. Unscrew and loosen the nut and clamp bolt which connects the lower arm balljoint at the Steering Knuckle, and, taking pains, lower the arm sufficiently to expose the balljoint clear of the knuckle clamp, whereupon the coil spring and spring seat may be withdrawn. Mark a point on the lower arm pivot bolt one relative to the subframe to create alignment marks on each of the two eccentric washers. Unscrew the lower arm pivot bolt nuts, take out the eccentric washers, and bolts, and record the orientation of each. One can then take off with the lower arm of the vehicle. Wipe the arm anywhere below the arm mountings, and the surrounding area, thoroughly, looking at the back, to ascertain whether there are cracks or distortions, or indications of wear or damage (though in the mounting bushes and balljoint this is not a strong concern, unless damaged). It might be necessary to request renewal, take the lower arm to a Mercedes-Benz dealer or other capable garage, because a hydraulic press and appropriate spacers will be needed, to press out and then install new bushes or balljoint. Test the gaiter covering the lower arm balljoint whether worn or damaged and replace accordingly. refit, providing the lower arm up and the front and rear pivot bolts and eccentric washers, ensuring in the right place on the subframe. Install the new nuts, clamping them firmly and so that the marks previously made are framed in the same direction as before removal. Clean the lower arm spring seat then install the upper arm spring to the coil spring and position the spring into place. Pull the lower end of the spring buttoned as much as possible against the end stop on the lower arm seat, line the upper restraint seat with the body conformity, and very gently jack up the lower arm while aligning the shank of the balljoint with the steering knuckle. Ensure that the coil spring is properly installed, the lower arm balljoint clamp bolt is placed and it is important to ensure that it is placed in position before connecting the new clamp bolt nut and tightening it to a set screw. Seal the steering knuckle clamp split on the inside with corrosive resistant sealant. Place the rubber mounting on the end of the antiroll bar, install it in lower arm clamp, mounting clamp and screw the new nuts onto it and tighten them to the desired amount. Rereach under the lower arm and thread the jack out as the striker releases the spring compressor, making sure that the ends of the springs are not mixed up. Install the roadwheel again, bring the vehicle back down to the floor and apply the wheel bolts to the recommended torque. Having the car on the wheels, rock it to loosen the lower arm into position, making sure the lower arm pivot bolt eccentric washers are correctly aligned with the marks created before removal, and screw on the two pivot bolt nuts to the required torque and install the engine undercover again. By a Mercedes-Benz dealer or any other garage equipped with appropriate tests, it is recommendable to check the front steering angles and wheel position as early as possible.