×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz C240 Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Oxygen Sensors found

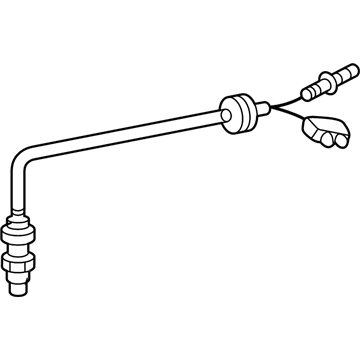

Mercedes-Benz C240 Rear Oxygen Sensor

Part Number: 001-540-74-17$290.40 MSRP: $404.00You Save: $113.60 (29%)Ships in 1-2 Business DaysMercedes-Benz C240 Oxygen Sensor

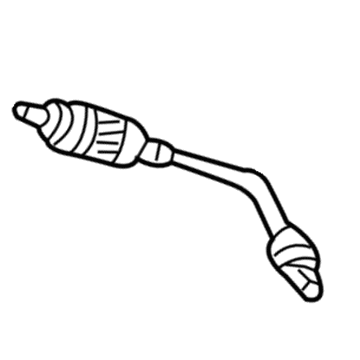

Part Number: 001-540-46-17$308.40 MSRP: $430.00You Save: $121.60 (29%)Ships in 1-2 Business DaysMercedes-Benz C240 Oxygen Sensor

Part Number: 001-540-50-17$296.40 MSRP: $412.00You Save: $115.60 (29%)

Mercedes-Benz C240 Oxygen Sensor

Every OEM part goes through strict quality checks. The checks keep you safe and make Oxygen Sensor tough. They keep performance the same as your original parts. If your Mercedes-Benz C240 needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz C240 parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz C240 Oxygen Sensor Parts and Q&A

- Q: What is the function and operation of an oxygen sensor on Mercedes-Benz C240?A:An oxygen sensor is essentially a galvanic battery, with the internal elements reacting to the unburned oxygen in the exhaust to produce a voltage output ranging between 0.1 volt (meaning the mixture is lean with lots of oxygen) and 0.9 volt (meaning the mixture is rich with near absent oxygen). Sixty-eight antibodies, mounted on the exhaust manifolds in front of the Catalytic Converters, provide feedback to the PCM about the amount of residual oxygen remaining, which the PCM uses to adjust the pulse width opened to the fuel injector to achieve maximum power, preferably that of an 14.7:1 air-fuel ratio to ensure ease of power and low levels of emissions. Sensors in array down the catalytic converters monitor catalytic efficiency, rather than attempt to control the air-fuel ratio, and generate a slow vibring voltage that measures the proportion of oxygen in the exhaust gases. Four sensors are used in V6 models, two in four-cylinder models and they are placed differently depending on the model year. Oxygen sensors need appropriate electrical connections, proper operating temperature (approximately 600-degrees F), unleaded fuel to perform best. The PCM is capable of detecting a wide range of sensor faults and enabling Diagnostic Trouble Codes to indicate a fault and shuts off open-loop fuel control when needed. To replace, it would be recommended to heat the engine so that the sensor is Warmed easy to remove electrical connector, be an appropriate tool which is the screwdriver and unscrew sensor, clean the thread and apply an anti-seize compound when re-using the old sensor. The reverse order is a good idea after installation, the torque should also be applied.