×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

Genuine Mercedes-Benz 190E Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

Mercedes-Benz 190E Crankshaft

Part Number: 102-030-21-01$1693.20 MSRP: $2360.00You Save: $666.80 (29%)

Mercedes-Benz 190E Crankshaft

Every OEM part goes through strict quality checks. The checks keep you safe and make Crankshaft tough. They keep performance the same as your original parts. If your Mercedes-Benz 190E needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 190E parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 190E Crankshaft Parts and Q&A

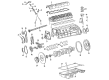

- Q: How to install the crankshaft based on engine type on Mercedes-Benz 190E?A:Next to take off: in 4-cylinder engines, sump, timing chain cover, timing chain, flywheel/driveplate; optionally, the crankshaft sprocket. In the case of a 6-cylinder petrol engine, detach the sump, oil pump, lower timing chain cover, timing chain, and flywheel/driveplate; and, should you wish, even the crankshaft sprocket. On diesel engines, disassembly is required of sump, oil pump, oil taffleplate (when fitted), timing chain cover, timing chain, flywheel/ driveplate; (when necessary) also of the crankshaft sprocket. Remove crankshaft rear oil seal housing attached to the cylinder block including the gasket. Disassemble the Pistons and connecting rods, projecting the pistons only sufficiently higher along the bores to clear the crankshaft journals in case no work is to be done on them. Check the crankshaft endfloat, the numbering of crankshaft bearing caps 1 to 5 4-cylinder engine, 1 to 6 5-cylinder engine, 1 to 7 6-cylinder engine then mark with a centre-punch so that they match up correctly with refitting, mark the bearers as follows: Move the covering of the main bearing nearer and scrape the main bearing bearing than remove all retaining bolts, lift the bearing caps one after another, retape bearing shells, tape to corresponding caps, marking where the re placement of the oil pick-up pipe support bracket is. Aprinter remove 1/2 of the lower endfloat control thrustwasher, one at a time, on either side of the right bearing cap, depending on the engine: 4-cylinder engines, centre main bearing cap, 5-cylinder engines, No 4 main bearing cap, No 5 main bearing cap, 6-cylinder engines. With considerable care lift out the crankshaft, which is some weight; and remove the upper bearing shells of the cylinder block, wrapping them up to the corresponding caps, to keep them safe, and also to regain the upper halves of the thrustwashers, marking the plate of their position.