×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

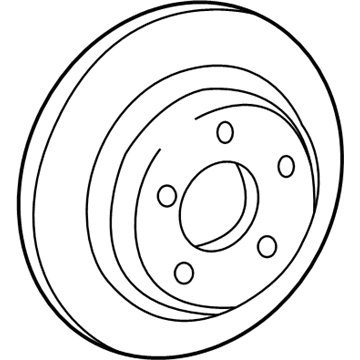

Genuine Mercedes-Benz 300TD Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Discs found

Mercedes-Benz 300TD Brake Rotor

Part Number: 115-421-13-12-64$114.00 MSRP: $159.00You Save: $45.00 (29%)Ships in 1-2 Business Days

Mercedes-Benz 300TD Brake Disc

Every OEM part goes through strict quality checks. The checks keep you safe and make Brake Disc tough. They keep performance the same as your original parts. If your Mercedes-Benz 300TD needs OEM parts, visit our catalog. You will find extensive genuine Mercedes-Benz 300TD parts. We offer a wide selection at competitive prices, and with clear fit details and simple guidance, choosing what you need is effortless. Each of our parts has a manufacturer's warranty. You will like our simple return policy. We pack and ship fast, and you get your order quickly. Shopping here feels easy and enjoyable.

Mercedes-Benz 300TD Brake Disc Parts and Q&A

- Q: How to inspect, remove, and install front and rear brake discs on Mercedes-Benz 300TD?A:In order to check the vehicle, it would be necessary to place it on the jackstands and put it up to have it stable, and then remove the wheel and tire. Unscrew the Brake Caliper assembly and suspend it off the work with a piece of wire, but not by the Brake Hose, which is easily damaged. Examine the brake disc surfaces, and have found some light scoring or grooving, and this is normal, however deep grooves or gross erosion are unacceptable. Should pulsating be detected when braking, then assume disc runout. Connect dial indicator to caliper mounting bracket and brake disc should be turned and runout should be read on inboard and outboard surfaces, adopted precautions is that in case the runout is greater than maximum allowable the brake disc has to be removed and refinished. Measure brake disc thickness using a micrometer, should be less than minimum requirement, should replace with a new one; check the disc thickness at various points, variation more than 0.0005-inch will lead to the development of pulsating in the pedals, and above all, check that the disc thickness is within the accepted range, then the brake disc can be reshaped. To remove, first remove the front brake disc, by removing the hub and then unbolstering the brake disc with an Allen head wrench, which may be clamped to a vise and penetrant oil applied to the bolts to be removed. Rear brake disc may be pulled off the hub, having first unscrewed the caliper; and in case it is not easily removed, push the parking brake shoes awayward of the inbuilt drum in the brake disc. New brake discs have some protective coating which can be sprayed off using carburetor cleaner and a rag. Installation is in the opposite sequence of removal so that the front brake disc bolts are tightened to the recommended torque and that the rear hub flange is lightly lubricated with moly-base grease before the brake disc is installed with special attention paid to getting the locating pin to snap securely into the hole.