×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

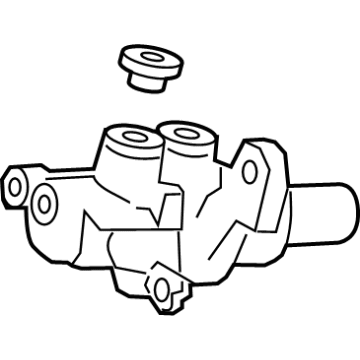

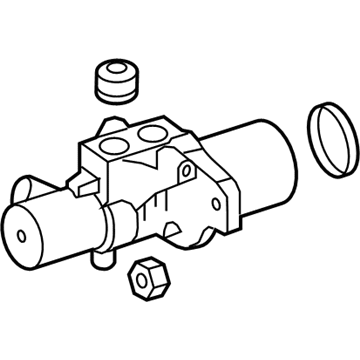

Genuine Mercedes-Benz Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

58 Brake Master Cylinders found

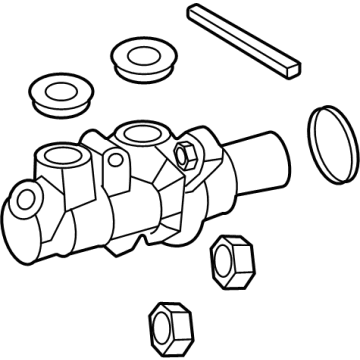

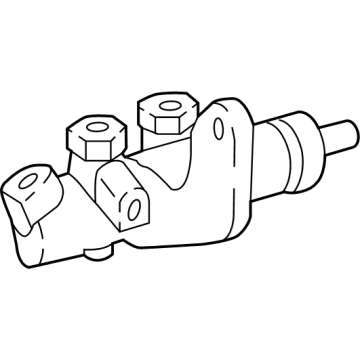

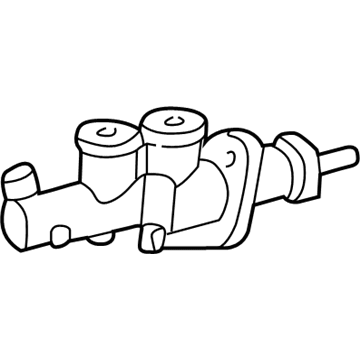

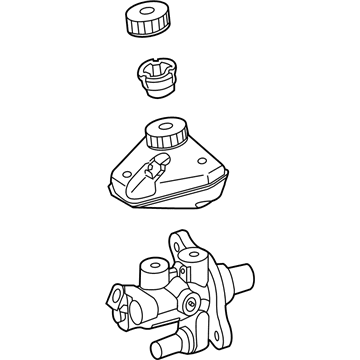

Mercedes-Benz Master Cylinder

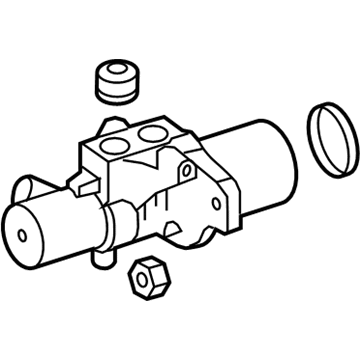

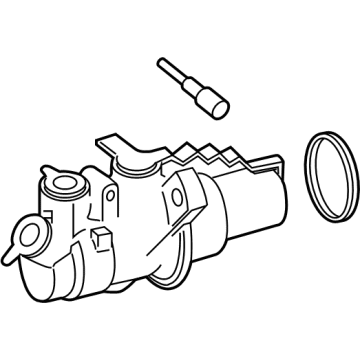

Part Number: 223-431-07-00$147.60 MSRP: $206.00You Save: $58.40 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rs Tandem Master Cylinder; Master Cylinder, Reservoir

Mercedes-Benz Master Cylinder

Part Number: 213-430-00-00$186.00 MSRP: $260.00You Save: $74.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder

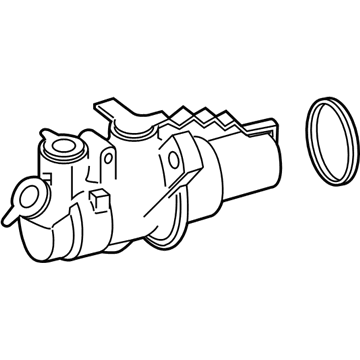

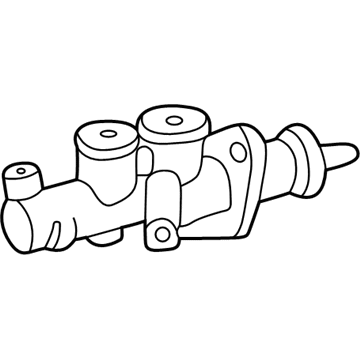

Mercedes-Benz Master Cylinder Assembly

Part Number: 204-430-05-01$186.00 MSRP: $260.00You Save: $74.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Brake Cylinder; Master Cylinder, Master Cylinder Assembly

- Replaces: 006-430-15-01

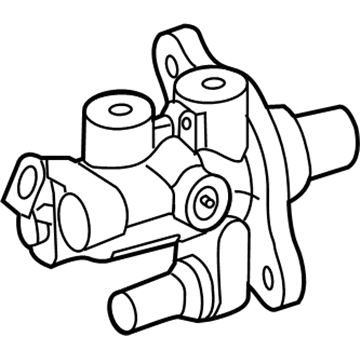

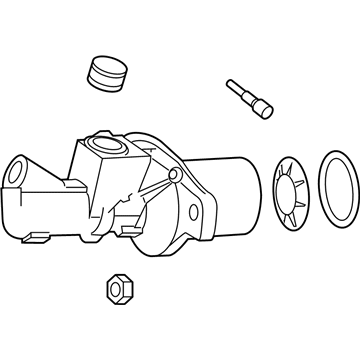

Mercedes-Benz Master Cylinder

Part Number: 205-430-00-01$195.60 MSRP: $272.00You Save: $76.40 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder

Mercedes-Benz Master Cylinder

Part Number: 221-430-03-01$193.20 MSRP: $270.00You Save: $76.80 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Master Cylinder; Master Cylinder

- Replaces: 221-430-00-01

Mercedes-Benz Master Cylinder

Part Number: 006-430-17-01$159.60 MSRP: $222.00You Save: $62.40 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Master Cylinder; Master Cylinder

- Replaces: 006-430-13-01

Mercedes-Benz Master Cylinder

Part Number: 005-430-88-01-64$201.60 MSRP: $280.00You Save: $78.40 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Cylinder; Master Cylinder

- Replaces: 005-430-88-01

Mercedes-Benz Master Cylinder

Part Number: 005-430-77-01$250.80 MSRP: $350.00You Save: $99.20 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Master Cylinder

Mercedes-Benz Master Cylinder

Part Number: 246-430-03-01$195.60 MSRP: $272.00You Save: $76.40 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder

Mercedes-Benz Master Cylinder

Part Number: 221-430-06-01$176.40 MSRP: $246.00You Save: $69.60 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder

Mercedes-Benz Master Cylinder

Part Number: 246-430-05-01$236.40 MSRP: $330.00You Save: $93.60 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder

Mercedes-Benz Master Cylinder

Part Number: 290-430-12-00$205.20 MSRP: $286.00You Save: $80.80 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder

Mercedes-Benz Master Cylinder

Part Number: 177-430-55-00$201.60 MSRP: $280.00You Save: $78.40 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Brake Cylinder; Master Cylinder

Mercedes-Benz Master Cylinder Assembly

Part Number: 212-430-08-01$212.40 MSRP: $296.00You Save: $83.60 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder, Master Cylinder Assembly

- Replaces: 212-430-00-01

Mercedes-Benz Master Cylinder

Part Number: 166-430-00-01$247.20 MSRP: $344.00You Save: $96.80 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder

Mercedes-Benz Master Cylinder

Part Number: 190-430-00-01$264.00 MSRP: $368.00You Save: $104.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder

Mercedes-Benz Master Cylinder

Part Number: 213-430-11-00$223.20 MSRP: $310.00You Save: $86.80 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder

Mercedes-Benz Master Cylinder

Part Number: 222-430-00-00$198.00 MSRP: $276.00You Save: $78.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TS Master Brake Cylinder; Master Cylinder

- Product Specifications

- Other Name: Brake Master Cylinder

- Replaces: 164-430-00-01, 164-430-03-01

- Product Specifications

- Other Name: Brake Master Cylinder

| Page 1 of 3 |Next >

1-20 of 58 Results

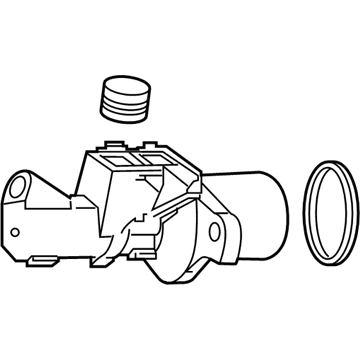

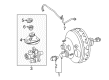

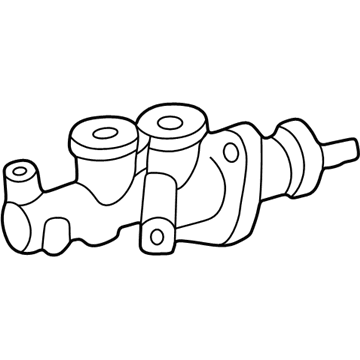

Mercedes-Benz Brake Master Cylinder

The brake master is a critical part of your vehicle's brakes. Once you step on the brakes, the pedal applies pressure, which is then converted into hydraulic pressure by the master cylinder by sending brake fluid through the lines. Quality Mercedes-Benz brake master cylinders made from top materials are designed to last; however, they eventually get worn out. An average repair cost ranges between $255 and $386 for professional repairs. However, there is a low-cost option of buying the part from us, doing the replacement yourself, and saving a lot of money.

Why go for OEM Mercedes-Benz Brake Master Cylinders? Because they are the optimal solutions, fit your vehicle perfectly, and are easy to install. Therefore, these factors help maintain the dependability and performance of your vehicle. At MBPartsGiant.com, you may find all the required genuine parts for your Mercedes-Benz. They are delivered from authorized Mercedes-Benz dealers directly via an uncomplicated online catalog. We guarantee promptness, reliability, and cheap sales on the Mercedes-Benz Brake Master Cylinder, and we always provide you with the right part at any time. Depend on our genuine Mercedes-Benz Brake Master Cylinders to keep your vehicle running smoothly.

Mercedes-Benz Brake Master Cylinder Parts and Q&A

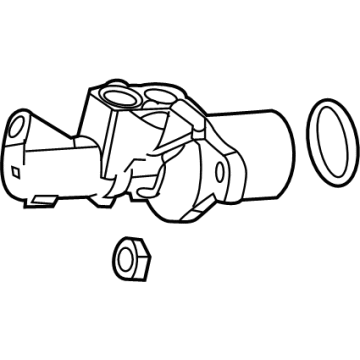

- Q: How to remove, overhaul, and refit of the Brake Master Cylinder on Mercedes-Benz 190E?A:You should know the hazards of hydraulic fluid before working on them. The first step should be to remove the battery negative terminal and the wiring connector on the level informer of brake fluid from the unit. Take out the master cylinder reservoir cap and siphon hydraulic fluid out of the reservoir, or open a bleed screw and press the brake pedal to pump the fluid out. When needed, remove the fluid hoses on the reservoir and seal off the ends in order to reduce leakage of fluids. Take your time when loading out the fluid reservoir of the master cylinder, do not touch the seals and seal the ports of the cylinder to avoid dirt infiltration. Clean up around the brake pipe unions, lay absorbent rags below them, record their correct locations, remove a union nut and take out the pipes, covering or taping the ends with rags to as much effect as possible not to lose the liquids or bring them inside. spindle and....... lifted away and then the two nuts and washers attaching the master cylinder to the vacuum servo unit, raising the unit up, take care not to tip over. Prior to assembling the master cylinder parts, verify the supply of spare parts as there are two types installed. Wipe the body of the master cylinder and the mounting seals on the fluid reservoir and record their proper locations. Hold the master cylinder body using a vice, and just press the piston in the cylinder to retract the secondary piston retaining pin. Download the piston with CIRclip, washer, and sealing ring, then take out the primary piston assembly and spring, and next the second piston and the spring, be notice of orientation. Wipe every part with appropriate cleaning pans even without using liquid based solvents and wipe them instantly. Inspect all parts of the design to determine if they are in good condition or worn or damaged, especially the cylinder bores, the pistons, etc., renewing those parts not in good condition. Just in case of the assembly is still usable, then get a repairing kit and re-do all the disrupted seals. Pre-pretreat the piston assemblies and new seals with clean hydraulic fluid and slide clean fluid into the cylinder bore during reassembly. Bend the spring to the secondary piston assembly and insert it by the master cylinder body with care not to entrap the piston seals. Place the secondary piston slot in place, slide it in place and then attach it with the retaining pin. Install the new primary piston assembly, and, where needed, install a new sealing ring at the end of the master cylinder and reinstall the washer and circlip, putting the circlip in the proper position. Insert the seals of the new fluid reservoir into the ports of the master cylinder. clean the mating-faces of the master cylinder and servo unit, replace old sealing ring on rear of master cylinder body and connect the master cylinder to servo unit, fitting them so they meet. Inspect (by refitting and tightening) the master cylinder retaining nuts, clean brake pipe unions and refit them to the master cylinder ports, and handfasten as directed. Then place the fluid reservoir in place and reconnect the fluid hoses as needed. Fill the master cylinder tank with new fluid and bleed the hydraulic system thoroughly, as the braking system has been tried and hence the car is ready to enter service again.

- Q: How to the remove and install of the Brake Master Cylinder on Mercedes-Benz C230?A:The master cylinder can be removed by disconnecting the cable under the negative battery terminal and depressing heavily the brake pedal a few times to wash out vacuum in the power brake booster. Mark the cover on the ground and then twist the fittings on the master cylinder counterclockwise by a quarter and then place some rags under the master cylinder and wipe the area around the hydraulic line fittings with brake system cleaner without touching any of the paint. Withdraw as much of the fluid as you can out of the reservoir with a syringe and un-plug electrical connector of a brake fluid level warning switch. On models with manual transmission, disconnect the brake fluid line that leads to the clutch master cylinder reservoir, stuff rags into the fittings and prepare the line ends with caps or plastic bags. To avoid flattening corners in the brake lines to the master cylinder, replace the fittings at the ends with ones loosened with a flare-nut wrench. Be sure to pull brake lines carefully away of the master-cylinder and plug the ends to prevent contamination. Unscrew the electrical connector on the side of the master cylinder that fits into the socket of the electronic stability program brake pressure device; and, installing a second sensor in the front, also, unscrew another connector attached to the master cylinder upon its loosening. You can take off the sensor on the side prepared to leak brake fluid and remove the spring nut at the end of the master cylinder and then push down the front bracket and pull them up off the frame. Unscrew the master cylinder mounting nuts and move the master cylinder off the studs, working carefully not to tip or drop the component against the pushrod in the power brake booster or risk their destruction. When the master cylinder has taken off, un-connect the electrical connector on the bottom-front ESP brake pressure sensor (where appropriate). To install, place the brake pressure sensor(s) on the new master cylinder, and bleed it by placing it in a vise and connecting bleeder tubes to the outlet ports and by pushing the piston into place with a blunt tool as you fill the reservoir with the suggested brake fluid. Make sure to push the pistons gradually into the master cylinder and expel all the air until no more bubbles exist, and then unscrew the bleed tubes and replace them with plugs in the empty holes. Install a new vacuum seal on the master cylinder, lay a cover over reservoir, attach electrical connectors and place the master cylinder on the studs on the power brake booster screwing on nuts using finger tightening. Install the brake line fittings into the master cylinder being careful not to cross-thread the fittings, and screw the mounting nuts to the correct level of tight. Fit a new spring-nut and re-attach the front bracket, so that it is rotated inward about 5 mm beyond the terminus of the master cylinder. Fill the reservoir with the appropriate fluid, bleed the brake system; do not open the line fittings immediately, but have an assistant pump the brake pedal, loosen the line fittings, one at a time, until all air is out of the fluid. Lastly, finish the installation reverse way that the process started and also examine the working of the brake system and then restore the car to normalcy.

Related Mercedes-Benz Parts

Browse by Model

190D Brake Master Cylinder 190E Brake Master Cylinder 260E Brake Master Cylinder 300CD Brake Master Cylinder 300CE Brake Master Cylinder 300D Brake Master Cylinder 300E Brake Master Cylinder 300SD Brake Master Cylinder 300SDL Brake Master Cylinder 300SE Brake Master Cylinder 300SEL Brake Master Cylinder 300SL Brake Master Cylinder 300TD Brake Master Cylinder 300TE Brake Master Cylinder 350SD Brake Master Cylinder 350SDL Brake Master Cylinder 400E Brake Master Cylinder 400SE Brake Master Cylinder 400SEL Brake Master Cylinder 420SEL Brake Master Cylinder 500E Brake Master Cylinder 500SEC Brake Master Cylinder 500SEL Brake Master Cylinder 500SL Brake Master Cylinder 560SEC Brake Master Cylinder 560SEL Brake Master Cylinder 600SEC Brake Master Cylinder 600SEL Brake Master Cylinder 600SL Brake Master Cylinder A220 Brake Master Cylinder A35 AMG Brake Master Cylinder AMG GT 43 Brake Master Cylinder AMG GT 53 Brake Master Cylinder AMG GT 63 Brake Master Cylinder AMG GT 63 S Brake Master Cylinder AMG GT 63 S E Performance Brake Master Cylinder AMG GT Black Series Brake Master Cylinder AMG GT Brake Master Cylinder AMG GT C Brake Master Cylinder AMG GT R Brake Master Cylinder AMG GT R Pro Brake Master Cylinder AMG GT S Brake Master Cylinder B Electric Drive Brake Master Cylinder B250e Brake Master Cylinder C220 Brake Master Cylinder C230 Brake Master Cylinder C240 Brake Master Cylinder C250 Brake Master Cylinder C280 Brake Master Cylinder C300 Brake Master Cylinder C32 AMG Brake Master Cylinder C320 Brake Master Cylinder C350 Brake Master Cylinder C350e Brake Master Cylinder C400 Brake Master Cylinder C43 AMG Brake Master Cylinder C450 AMG Brake Master Cylinder C55 AMG Brake Master Cylinder C63 AMG Brake Master Cylinder C63 AMG S Brake Master Cylinder CL500 Brake Master Cylinder CL55 AMG Brake Master Cylinder CL550 Brake Master Cylinder CL600 Brake Master Cylinder CL63 AMG Brake Master Cylinder CL65 AMG Brake Master Cylinder CLA250 Brake Master Cylinder CLA35 AMG Brake Master Cylinder CLA45 AMG Brake Master Cylinder CLK320 Brake Master Cylinder CLK350 Brake Master Cylinder CLK430 Brake Master Cylinder CLK500 Brake Master Cylinder CLK55 AMG Brake Master Cylinder CLK550 Brake Master Cylinder CLK63 AMG Brake Master Cylinder CLS400 Brake Master Cylinder CLS450 Brake Master Cylinder CLS500 Brake Master Cylinder CLS53 AMG Brake Master Cylinder CLS55 AMG Brake Master Cylinder CLS550 Brake Master Cylinder CLS63 AMG Brake Master Cylinder CLS63 AMG S Brake Master Cylinder E250 Brake Master Cylinder E300 Brake Master Cylinder E320 Brake Master Cylinder E350 Brake Master Cylinder E400 Brake Master Cylinder E420 Brake Master Cylinder E43 AMG Brake Master Cylinder E430 Brake Master Cylinder E450 Brake Master Cylinder E500 Brake Master Cylinder E53 AMG Brake Master Cylinder E55 AMG Brake Master Cylinder E550 Brake Master Cylinder E63 AMG Brake Master Cylinder E63 AMG S Brake Master Cylinder EQB 250 Brake Master Cylinder EQB 300 Brake Master Cylinder EQB 350 Brake Master Cylinder EQE 350 Brake Master Cylinder EQE 350 SUV Brake Master Cylinder EQE 350+ Brake Master Cylinder EQE 350+ SUV Brake Master Cylinder EQE 500 Brake Master Cylinder EQE 500 SUV Brake Master Cylinder EQE AMG Brake Master Cylinder EQS 450 Brake Master Cylinder EQS 450 SUV Brake Master Cylinder EQS 450+ Brake Master Cylinder EQS 450+ SUV Brake Master Cylinder EQS 580 Brake Master Cylinder EQS 580 SUV Brake Master Cylinder EQS AMG Brake Master Cylinder G500 Brake Master Cylinder G55 AMG Brake Master Cylinder G550 Brake Master Cylinder G63 AMG Brake Master Cylinder G65 AMG Brake Master Cylinder GL320 Brake Master Cylinder GL350 Brake Master Cylinder GL450 Brake Master Cylinder GL550 Brake Master Cylinder GL63 AMG Brake Master Cylinder GLA250 Brake Master Cylinder GLA35 AMG Brake Master Cylinder GLA45 AMG Brake Master Cylinder GLB250 Brake Master Cylinder GLB35 AMG Brake Master Cylinder GLC300 Brake Master Cylinder GLC350e Brake Master Cylinder GLC43 AMG Brake Master Cylinder GLC63 AMG Brake Master Cylinder GLC63 AMG S Brake Master Cylinder GLE300d Brake Master Cylinder GLE350 Brake Master Cylinder GLE400 Brake Master Cylinder GLE43 AMG Brake Master Cylinder GLE450 AMG Brake Master Cylinder GLE450 Brake Master Cylinder GLE53 AMG Brake Master Cylinder GLE550e Brake Master Cylinder GLE580 Brake Master Cylinder GLE63 AMG Brake Master Cylinder GLE63 AMG S Brake Master Cylinder GLK250 Brake Master Cylinder GLK350 Brake Master Cylinder GLS350d Brake Master Cylinder GLS450 Brake Master Cylinder GLS550 Brake Master Cylinder GLS580 Brake Master Cylinder GLS63 AMG Brake Master Cylinder ML250 Brake Master Cylinder ML320 Brake Master Cylinder ML350 Brake Master Cylinder ML400 Brake Master Cylinder ML430 Brake Master Cylinder ML450 Brake Master Cylinder ML500 Brake Master Cylinder ML55 AMG Brake Master Cylinder ML550 Brake Master Cylinder ML63 AMG Brake Master Cylinder R320 Brake Master Cylinder R350 Brake Master Cylinder R500 Brake Master Cylinder R63 AMG Brake Master Cylinder S320 Brake Master Cylinder S350 Brake Master Cylinder S400 Brake Master Cylinder S420 Brake Master Cylinder S430 Brake Master Cylinder S450 Brake Master Cylinder S500 Brake Master Cylinder S55 AMG Brake Master Cylinder S550 Brake Master Cylinder S550e Brake Master Cylinder S560 Brake Master Cylinder S560e Brake Master Cylinder S580e Brake Master Cylinder S600 Brake Master Cylinder S63 AMG Brake Master Cylinder S65 AMG Brake Master Cylinder SL320 Brake Master Cylinder SL400 Brake Master Cylinder SL450 Brake Master Cylinder SL500 Brake Master Cylinder SL55 AMG Brake Master Cylinder SL550 Brake Master Cylinder SL600 Brake Master Cylinder SL63 AMG Brake Master Cylinder SL65 AMG Brake Master Cylinder SLC300 Brake Master Cylinder SLC43 AMG Brake Master Cylinder SLK230 Brake Master Cylinder SLK250 Brake Master Cylinder SLK280 Brake Master Cylinder SLK300 Brake Master Cylinder SLK32 AMG Brake Master Cylinder SLK320 Brake Master Cylinder SLK350 Brake Master Cylinder SLK55 AMG Brake Master Cylinder Sprinter 1500 Brake Master Cylinder Sprinter 2500 Brake Master Cylinder Sprinter 3500 Brake Master Cylinder Sprinter 3500XD Brake Master Cylinder