×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Mercedes-Benz Parts

My Garage

My Account

Cart

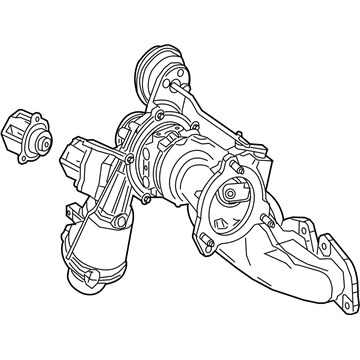

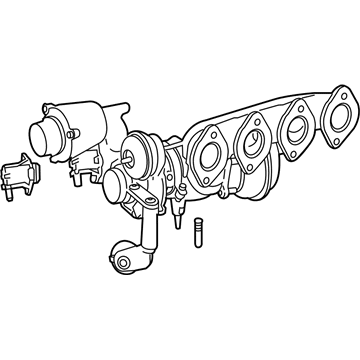

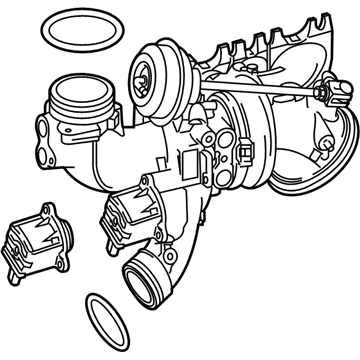

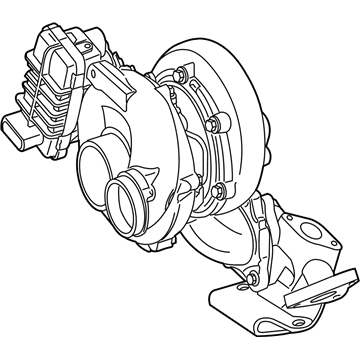

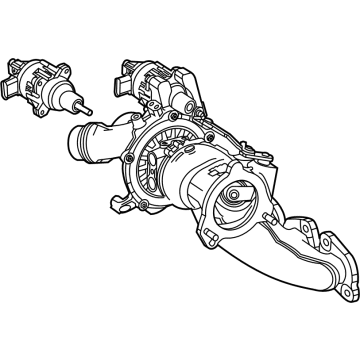

Genuine Mercedes-Benz Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

78 Turbochargers found

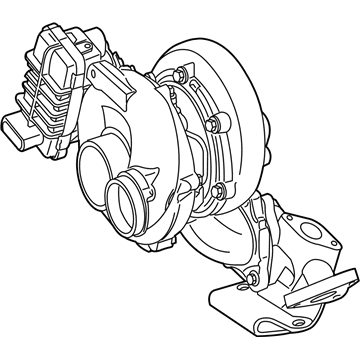

Mercedes-Benz Turbocharger

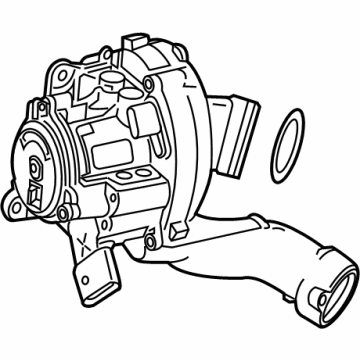

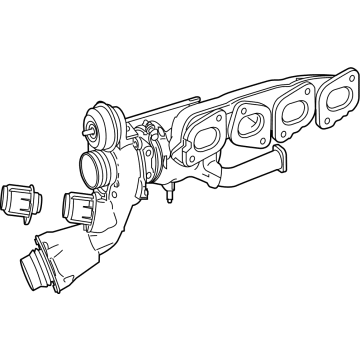

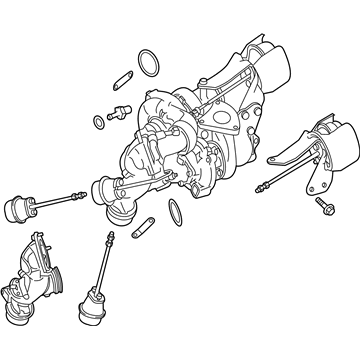

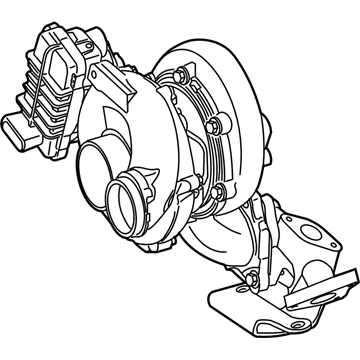

Part Number: 254-090-89-00$1476.00 MSRP: $2050.00You Save: $574.00 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Additional Compressor; Turbocharger

- Replaced by: 254-090-15-01

Mercedes-Benz Turbocharger

Part Number: 276-090-04-00$4020.00 MSRP: $5590.00You Save: $1570.00 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

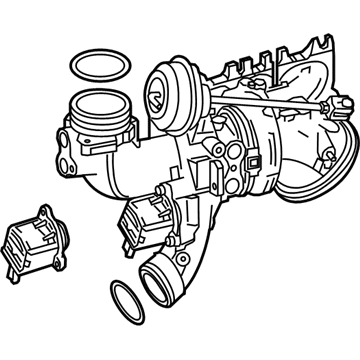

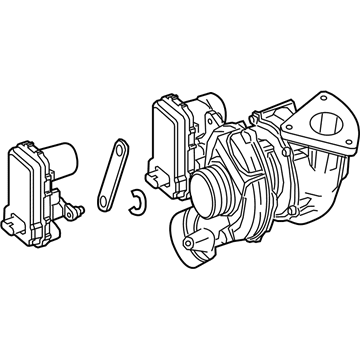

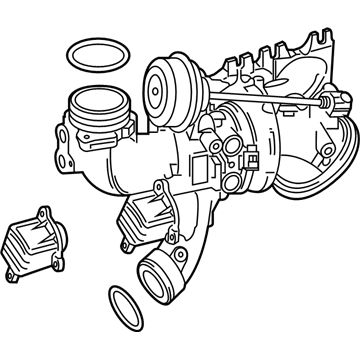

Part Number: 264-090-37-00$1608.00 MSRP: $2240.00You Save: $632.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Exhaust Gas Turbocharger; Turbocharger

Mercedes-Benz Turbocharger

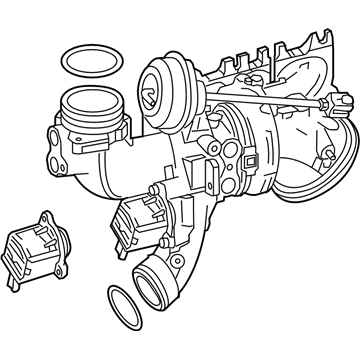

Part Number: 276-090-33-80-80$1798.85 MSRP: $2500.00You Save: $701.15 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Reman Turbocharger; Turbocharger

- Replaces: 276-090-33-80, 276-090-15-80

Mercedes-Benz Turbocharger

Part Number: 651-090-61-80-88$1532.16 MSRP: $2128.00You Save: $595.84 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Reman Turbocharger; Turbocharger

- Replaced by: 651-090-61-80-87

- Replaces: 651-090-61-80-80, 651-090-61-80, 651-090-61-80-87

Mercedes-Benz Turbocharger

Part Number: 651-090-70-80-87$1552.03 MSRP: $2150.00You Save: $597.97 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Reman Exhaust Gas Turbocharger; Turbocharger

- Replaced by: 651-090-70-80-88

- Replaces: 651-090-70-80-80, 651-090-70-80-88, 651-090-70-80

Mercedes-Benz Turbocharger

Part Number: 270-090-29-80-80$1680.00 MSRP: $2340.00You Save: $660.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Reman Turbocharger; Turbocharger

- Replaced by: 270-090-29-80

- Replaces: 270-090-29-80, 270-090-18-80, 270-090-18-80-80

Mercedes-Benz Turbocharger

Part Number: 271-090-36-80-80$1519.53 MSRP: $2108.00You Save: $588.47 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Reman Turbocharger; Turbocharger

- Replaces: 271-090-36-80

Mercedes-Benz Turbocharger

Part Number: 276-090-41-80$4020.00 MSRP: $5590.00You Save: $1570.00 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

Part Number: 139-090-35-00$4020.00 MSRP: $5590.00You Save: $1570.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Exhaust Gas Turbocharger; Turbocharger

Mercedes-Benz Turbocharger

Part Number: 276-090-19-00$2710.32 MSRP: $3770.00You Save: $1059.68 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

Part Number: 276-090-20-00$2842.56 MSRP: $3950.00You Save: $1107.44 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

Part Number: 276-090-40-80$2930.72 MSRP: $4062.00You Save: $1131.28 (28%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 276-090-28-80

Mercedes-Benz Turbocharger

Part Number: 276-090-29-80$4020.00 MSRP: $5590.00You Save: $1570.00 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

Part Number: 276-090-03-00$2796.00 MSRP: $3890.00You Save: $1094.00 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

Part Number: 642-090-87-80$3029.25 MSRP: $4202.00You Save: $1172.75 (28%)Product Specifications- Replaced by: 642-090-86-80

Mercedes-Benz Turbocharger

Part Number: 260-090-42-00$3012.00 MSRP: $4190.00You Save: $1178.00 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Exhaust Gas Turbocharger; Turbocharger

- Replaces: 260-090-30-00

Mercedes-Benz Turbocharger

Part Number: 642-090-21-80$3029.25 MSRP: $4202.00You Save: $1172.75 (28%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 642-090-86-80

Mercedes-Benz Turbocharger

Part Number: 276-090-16-80$2917.20 MSRP: $4060.00You Save: $1142.80 (29%)Ships in 1-2 Business DaysMercedes-Benz Turbocharger

Part Number: 642-090-63-80$3029.25 MSRP: $4202.00You Save: $1172.75 (28%)Product Specifications- Replaced by: 642-090-86-80

| Page 1 of 4 |Next >

1-20 of 78 Results

Mercedes-Benz Turbocharger

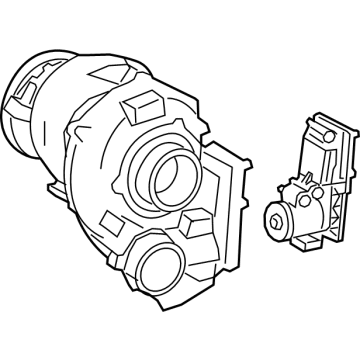

Every part of the automobile matters, and their maintenance is crucial for the health of your vehicle. Moreover, a faulted Mercedes-Benz Turbocharger can impact its functionality as well as lead to system-wide problems that may endanger safety. Thus, it is imperative that one repairs or replaces failing parts for better driving experiences. Why go for OEM Mercedes-Benz Turbochargers? Because they are the optimal solutions, fit your vehicle perfectly, and are easy to install. Therefore, these factors help maintain the dependability and performance of your vehicle. At MBPartsGiant.com, you may find all the required genuine parts for your Mercedes-Benz. They are delivered from authorized Mercedes-Benz dealers directly via an uncomplicated online catalog. We guarantee promptness, reliability, and cheap sales on the Mercedes-Benz Turbocharger, and we always provide you with the right part at any time. Depend on our genuine Mercedes-Benz Turbochargers to keep your vehicle running smoothly.

Mercedes-Benz Turbocharger Parts and Q&A

- Q: What are the key considerations and symptoms to monitor for maintaining a turbocharger on Mercedes-Benz 300TD?A:The relative simplicity of the turbocharge is a precision device which can take a great deal of punishment with a cut-off ot omitted oil feed, and loose fitting and damaged ducting. A dealer should check suspected problems because of the specialized tools and equipment that work with them, however, a home mechanic could examine the connections and linkages to check their security, damage, or apparent faultiness. The sound of any turbocharger is peculiar, and any alteration in the sound level can become a symptom of something wrong. A whistling or high-pitched sound will indicate leaking of inlet air or exhaust gas through the air ducting that passes over the air cleaner to the end connected to the exhaust manifold that has become loose or has been punctured by an object, a low engine power will be an indication that the air ducting between the air cleaner and the connection of the duct to the exhaust manifold has become loose or has been poked by an object. Oil in the intake or exhaust or white exhaust smoke is an indication of a broken internal seal in the turbocharger. Should there be unusual sounds in the turbine region, the ducting may be removed, thus enabling an inspection to be made of the turbine wheel which should turn freely; a binding will show that the cooling oil has become sludged up, or coked due to overheating. Cracks and loose fittings on the exhaust manifold also need to be inspected. Since the turbine can efficiently reach 140000 rPM, any break in the oil supply or pollution to the oil bearing shafts can cause serious damage therefore it should be noted that leaks in the oil return pipe and a blockage that may cost the turbine a significant amount of oil via the turbocharger seals can result in a clear sign of burned oil on the turbine housing. Moreover, whenever changing a large engine bearing, it is always necessary to empty the turbocharger with clean oil.

Related Mercedes-Benz Parts

Browse by Model

190D Turbocharger 300D Turbocharger 300SD Turbocharger 300SDL Turbocharger 300TD Turbocharger 420SEL Turbocharger 560SEL Turbocharger A35 AMG Turbocharger AMG GT 43 Turbocharger AMG GT 53 Turbocharger AMG GT 63 S E Performance Turbocharger AMG GT 63 S Turbocharger AMG GT 63 Turbocharger AMG GT Black Series Turbocharger AMG GT C Turbocharger AMG GT R Pro Turbocharger AMG GT R Turbocharger AMG GT S Turbocharger AMG GT Turbocharger C250 Turbocharger C300 Turbocharger C350e Turbocharger C400 Turbocharger C43 AMG Turbocharger C450 AMG Turbocharger C63 AMG S Turbocharger C63 AMG Turbocharger CL55 AMG Turbocharger CL550 Turbocharger CL600 Turbocharger CL63 AMG Turbocharger CL65 AMG Turbocharger CLA250 Turbocharger CLA35 AMG Turbocharger CLA45 AMG Turbocharger CLS400 Turbocharger CLS450 Turbocharger CLS53 AMG Turbocharger CLS55 AMG Turbocharger CLS550 Turbocharger CLS63 AMG S Turbocharger CLS63 AMG Turbocharger E250 Turbocharger E300 Turbocharger E320 Turbocharger E350 Turbocharger E400 Turbocharger E43 AMG Turbocharger E450 Turbocharger E53 AMG Turbocharger E55 AMG Turbocharger E550 Turbocharger E63 AMG S Turbocharger E63 AMG Turbocharger G55 AMG Turbocharger G550 Turbocharger G63 AMG Turbocharger G65 AMG Turbocharger GL320 Turbocharger GL350 Turbocharger GL450 Turbocharger GL550 Turbocharger GL63 AMG Turbocharger GLA250 Turbocharger GLA35 AMG Turbocharger GLA45 AMG Turbocharger GLB35 AMG Turbocharger GLC300 Turbocharger GLC350e Turbocharger GLC43 AMG Turbocharger GLC63 AMG S Turbocharger GLC63 AMG Turbocharger GLE300d Turbocharger GLE350 Turbocharger GLE400 Turbocharger GLE43 AMG Turbocharger GLE450 AMG Turbocharger GLE450 Turbocharger GLE53 AMG Turbocharger GLE550e Turbocharger GLE580 Turbocharger GLE63 AMG S Turbocharger GLE63 AMG Turbocharger GLK250 Turbocharger GLS450 Turbocharger GLS550 Turbocharger GLS580 Turbocharger GLS63 AMG Turbocharger ML250 Turbocharger ML320 Turbocharger ML350 Turbocharger ML400 Turbocharger ML550 Turbocharger ML63 AMG Turbocharger Metris Turbocharger R320 Turbocharger R350 Turbocharger S350 Turbocharger S450 Turbocharger S55 AMG Turbocharger S550 Turbocharger S550e Turbocharger S560 Turbocharger S560e Turbocharger S580 Turbocharger S580e Turbocharger S600 Turbocharger S63 AMG Turbocharger S65 AMG Turbocharger SL400 Turbocharger SL450 Turbocharger SL55 AMG Turbocharger SL550 Turbocharger SL600 Turbocharger SL63 AMG Turbocharger SL65 AMG Turbocharger SLC300 Turbocharger SLC43 AMG Turbocharger SLK250 Turbocharger SLK300 Turbocharger SLK350 Turbocharger SLK55 AMG Turbocharger Sprinter 1500 Turbocharger Sprinter 2500 Turbocharger Sprinter 3500 Turbocharger Sprinter 3500XD Turbocharger